-

Other finance solutions

-

Equipment

-

- Become a Partner

-

About SilverChef

buyer's guide

Whether you’re crafting a classic meat pie, a signature pizza, or a delicate pastry, a commercial dough roller or dough sheeter can be the difference between a good bake and a great one.

Designed for efficiency and consistency, these machines are built to handle large volumes, making them indispensable for food businesses aiming for consistent quality.

This comprehensive commercial dough roller and dough sheeter buying guide, dives deep into the nuances of selecting the ideal equipment for your business.

From understanding core functionalities and exploring various types and styles to discussing top brands, we'll guide you through every purchase consideration.

By the end, you'll be well-equipped to decide not only on the best machines to fit your business’s unique needs but also see the value in considering leasing or renting, used equipment.

Let’s get started.

A dough roller machine is benchtop equipment designed only for rolling dough and is best suited for cranking out a high volume instantly.

These machines are more focused on rapid production than the thickness or consistency of the final product.

Dough roller machines are common in restaurants and pizza shops that serve rolls, different types of bread, and pizza in high volume but do not need an extra-thin, consistent dough sheet for the menu items.

Some of the common types of dough rollers used in commercial food service environments include the following.

The simplest manual version of a dough roller is a tool that combines a roller with a handle to facilitate the process of rolling dough.

Although they are handy in small-scale applications, like artisanal pastry making, they’re not as efficient or speedy as their electric counterparts.

These tools with single or double-rolling pins, can be effective for small pastry or pizza shops.

These compact, electric dough rollers, also known as pizza dough roller machines, come with a single roller and are designed to quickly shape the dough for pizza, bread, or smaller pies.

They have a single rolling pin.

The minimum and maximum diameter of the dough shape that can be produced with these rollers depends on the size and other specifications of the unit.

The electric dough roller machines with double rolling pins produce more uniform dough thickness.

The use of two pins also enables it to produce thinner dough bases without tearing.

The rollers might be parallel to each other or inclined depending on the model.

These dough rollers are also known as pizza dough rollers or pizza dough sheeters.

These are a specialised variety of dough rollers designed to focus on rolling thin dough sheets for pasta.

They usually come with an additional sheet cutter attachment with different cutting sizes for cutting the dough sheets into thin pasta strips.

Depending on the model, these electric dough rollers can be used for making pizza, bread, and pastry sheets as well.

A commercial dough sheeter, also known as a pastry sheeter, is a machine designed to produce a consistently thin sheet of dough for pastries, flatbread, thin-crust pizza, laminated dough products, or other items that need dough sheets of specific thickness.

These machines often come with adjustable speed and thickness, allowing you to produce dough sheets according to the recipe and demand.

Commercial dough sheeter machines are versatile and commonly used only in large-scale industrial bakeries, pizzerias, and other food services.

A large dough sheeter generally has three main sections: the roller assembly, the belt conveyor, and the frame.

The roller assembly includes two or more rollers and roller guards.

When turned on, each of the rollers rotates around an axis and presses the dough to produce a sheet of a specific thickness.

The belt conveyor holds and transports the dough.

There’s also a dough tray just underneath the belt in some models.

The primary purpose of the frame is to hold all the components together and provide support for the machine to work smoothly.

There are typically two types of dough sheeter machines common in commercial setups.

As the name suggests, these are hand-operated and the user needs to manually turn a crank to feed the dough through the rollers.

They are often less expensive and have a lower operational cost compared to the electrical models.

However, they need more effort to operate and will produce dough sheets at a much slower rate than an electric machine.

Electric dough sheeters are equipped with an electricity-powered motor that automates the process.

These are highly efficient and need less effort to operate compared to the manual sheeters.

However, they are more expensive to run.

Electric dough sheeter machines are ideal for large bakeries, pizzerias, and other food services requiring high-volume production.

The two common styles of commercial dough sheeter machines are:

These are heavy-duty machines designed to meet the high-volume needs of large bakeries and other high-scale operations.

These dough sheeters come with their own stand and offer high production capacity.

However, they are not suitable for smaller production units, due to the large size.

Plus, they are often more expensive than the benchtop variants.

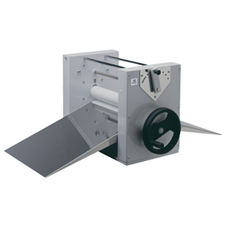

These are more compact and easily portable versions of the floor-standing dough sheeters.

They come with similar parts except for the stand and need to be placed on a levelled bench or tabletop for operation.

These models are suitable for bakeries and food establishments with limited kitchen space.

|

Feature/Aspect |

Commercial dough roller machine |

Commercial dough sheeter machine |

|

Application |

Primarily used to quickly roll dough into discs or sheets of uniform thickness for rolls, bread, pizza bases, etc. |

Used to flatten the dough into thin sheets for pastries, croissants, other laminated dough products, thin-crust pizzas, etc. |

|

Footprint |

More compact in design and typically countertop based. |

Electric models are larger in size. Both floor and benchtop models require more space. |

|

Price |

It is less expensive than a large dough sheeter machine. A decent model will cost approximately $1,500 - $3,500, depending on the make and model. |

It is more expensive. A benchtop electric model will cost upwards of $5,500, while a floor standing one may cost over $10,000. It depends on the features and brand. |

Depending on the size of the business and the menu served, your food service might need a dough roller, a dough sheeter, or both machines.

If your business primarily involves serving rolls, loaves of bread, or pizza, a dough roller machine is what you’ll need.

These are ideal for restaurants, medium-sized bakeries, and pizza shops that do not require thin dough sheets or dough sheets of a consistent thickness in high volume, but need more production that can’t be achieved with hand rolling.

If your business specifically serves pasta and pizza, consider a pasta dough roller.

A large industrial dough sheeter machine, on the other hand, specializes in producing dough sheets of an adjustable specific thickness consistently.

These are used in large industrial bakeries and food services that serve different types of pastries, croissants, flatbread, or other laminated dough products requiring dough sheets of a specific thickness for a good bake.

These are also ideal for pizza-making units producing thin-crust pizzas in high volume.

If you run a large business that produces a wide variety of dough-based items requiring both thin dough sheets (for laminated dough products, pastries, etc.) and uniformly rolled dough discs (for pizza, rolls, bread, etc.) in high volume, you might need both the machines to fit all the requirements efficiently.

When you are in the market to buy a commercial dough roller or dough sheeter machine for your food service business, you should consider the following features:

When it comes to commercial kitchen equipment, quality is paramount.

A dough roller or dough sheeter machine is often expected to work the whole day as per demand without causing any extra stress on the system.

Choosing a machine from a top brand is certainly the easiest way to ensure that you’re investing in equipment of high quality.

Look for stainless steel construction.

It is corrosion-resistant, food-safe, and easy to clean. Dough rollers might use aluminium alloy as well, which is cheaper.

Consider the material of the rollers and the roller guards which might vary according to the make.

Some models come with resin rollers.

They might also have a non-stick coating for better functionality.

The roller guards are commonly made of stainless steel or plexiglass.

The manual dough rollers can be made of stainless steel, wood, or food-grade plastic.

A combination of stainless steel and aluminium alloy might be used in the construction of these heavy-duty units.

A machine with a stainless steel frame is sturdier.

The material of the conveyor belt is another point to consider.

Cotton sheeter belts are common and offer easy dough release but they might tear more quickly.

Belts made of a blend of cotton and polyurethane (PU) or polyester are stronger and offer better longevity.

Food-safe PVC belts are affordable, while PU belts also show high oil and abrasion resistance.

Food-grade Teflon belts are another popular choice.

Consider the type of product you’ll make to decide the best belt material for you.

Commercial dough roller and dough sheeter machines are available in multiple sizes and capacities.

You need to choose a model that fits comfortably within the available space in your kitchen and matches your business's production requirements.

The minimum and maximum size of a commercial dough roller machine can vary depending on the specific model.

In general, table-top models often have a width of between 304mm to 635mm.

The larger machines are typically capable of producing larger dough discs.

The size of a dough sheeter machine depends on the width of the conveyor belt and the length of the table.

Each of these features varies according to the make and model.

Dough sheeters with a belt width of around 475mm to 630mm are common, while the length of the table is often in the range of 830mm to 1200mm, for the floor-standing models.

The bigger the size, the more dough it can handle at a time.

The capacity of the machine should be according to the volume of production you need daily or during peak times.

The capacity is typically proportionate with the size.

A compact, tabletop dough roller can produce as many as 250 pcs of dough sheets per hour depending on the make and model.

A larger model can handle around 900gm or more dough weight in a single feed.

A bench dough sheeter from a good brand can usually handle 3-5 Kg dough block weight, whereas a medium-sized floor dough sheeter can usually work with more than 6 kg of dough depending on the brand and model.

The settings and controls of a dough roller or dough sheeter machine determine the flexibility and efficiency of the unit.

It also dictates if the operation of the system is simple enough to achieve your desired output.

In a professional setup, different types of cuisine are prepared and each item might need a different dough shape and thickness.

Ensure that the dough roller machine has easy thickness control and speed control options. This will help you do more with the same machine.

Different items, like pizza, pie, cookies, and pastries need different dough thicknesses and even the same dish might have variants that demand thinner or thicker dough sheets.

Confirm that your dough sheeter machine has an adjustable dough thickness feature and does not limit you to a standard thickness.

Adjustable roller gaps and easy speed control are also necessary.

Some advanced commercial dough sheeter machines also offer temperature control settings for adjusting the temperature of the dough sheet as it passes through the machine.

This helps to achieve the desired texture and consistency.

Proper attachments and accessories can make your dough sheeter more versatile and efficient.

Some of the common attachments and accessories include:

Cutting blades: These blades are used for cutting and shaping the dough sheet according to the product requirements.

Scraper blades: The purpose of the scraper blades is to scrape off any extra dough from the rollers.

Safety guards: These coverings are present over the rollers to prevent fingers or clothing from getting stuck and causing an accident.

Dough trays: Dough trays are used to hold the dough.

Also, consider the following aspects before you order a commercial dough roller or dough sheeter machine.

The noise produced by a commercial dough roller or dough sheeter machine often depends on the make and model.

For the larger dough sheeters, the noise produced by the motor and rollers can be considerable.

However, some high-end units are engineered to produce less noise and are quieter.

It is always advisable to choose a machine that produces less noise to ensure a more comfortable work environment.

Energy-efficient commercial kitchen equipment might cost you a bit extra, but they save on electricity bills.

Get a model that has low energy consumption.

Dough rollers and sheeters with timers can be helpful to save energy by turning off the machine automatically once the process is complete.

Safety features are a vital consideration when buying a dough roller or dough sheeter machine.

Commercial dough roller and dough sheeter machines from prominent brands typically include features like emergency stop buttons, roller safety guards, locking casters, and automatic shut-off.

Overload protection and thermal protection are some other safety features found in larger dough sheeters.

Regular cleaning of your dough roller or sheeter machine is vital to ensure food hygiene and the longevity of the unit.

Get a machine that comes with easily removable parts that you can quickly take out for cleaning.

Prismafood is a leading European player in the professional kitchen equipment sector.

Established in 2006, this Italy-based brand has become a prominent choice owing to their strict quality standards.

Prismafood machines are engineered to work efficiently in demanding commercial setups.

In Australia, FED is the primary distributor for Prismafood pizza dough roller machines.

Prismafood pizza dough rollers are available in the DSA and DMA series.

The DMA310 - 1 pizza dough roller, is a compact, single roller machine designed to quickly shape dough for 14-30 cm (diameter) pizzas, cakes, breads, and small pies. Featuring a gear transmission system and adjustable thickness (0-5mm), this pizza dough roller is a good choice for smaller bakeries and pizza shops.

The DSA500RP Prismafood pizza dough roller machine is a popular choice for medium to large establishments. Featuring thermal motor protection and a foot pedal, this model is capable of producing 26-45cm (diameter) pizza bases and can handle 220g to 900g dough weight.

Check out more Prismafood dough rollers here.

Rondo is a Swiss company known for their expertise in manufacturing high-tech professional dough machines since 1948.

They depend on continuous research and development and combine their baking expertise with leading industry innovations to deliver the best quality and precision.

Moffat is the primary importer and distributor of Rondo dough sheeter machines in Australia.

The brand has an extensive range of dough sheeters to meet medium to high-volume professional needs.

Rondo STM5303 - Econom 4000 benchtop sheeter is known for its sturdy design and technology that ensures efficient service for years. With side push-button control, fold-up tables, and bench-mounted design it fits even in compact kitchens.

Rondo SSO5304 Econom 4000 mobile floor sheeter is another stand out model. It comes with 100 program operations and includes an automatic flour duster. Featuring optional variable speed sheeting, it can handle 6 – 12.5 kg dough weight. The other model, Rondo SSH7907H - Compas 4.0 Expert is a programmable dough sheeter with a digital display and I-touch operating screen. It’s ideal for large industrial bakeries and food services looking for a high-tech dough sheeting machine.

Check out more Rondo dough sheeters here.

Fimar is a global brand serving the commercial machinery designing and manufacturing market for over 40 years.

This Italy-based company manufactures a range of dough rollers, including specialised pasta and pizza dough rollers.

Fimar dough rollers are known for the best quality parts and powerful service under demanding commercial environments.

Fimar pizza dough roller machine FIP42N is a good choice for busy businesses serving pizza and different types of bread. With a complete stainless steel structure and food-safe, resin-made rollers, this bench-top model is an efficient solution that can save considerable time. The more compact model, FI32N with inclined rollers is also a popular choice.

The pasta and pizza dough roller machine, Fimar SI320, is a reliable solution for food businesses serving both pasta and pizzas. This compact tabletop dough roller also has a single sheet cutter attachment with different cutting sizes for easy pasta preparation.

Check out more Fimar dough rollers here.

Mecnosud is an Italian manufacturer of commercial kitchen equipment, with over 40 years of experience.

They are a leading supplier of dough roller and dough sheeter machines, spiral mixers, and other bakery equipment.

Mecnosud's products are known for their quality, durability, and versatility.

They are used by restaurants, bakeries, and food service businesses all over the world.

Mecnosud manufactures a complete range of dough rollers. The DL series covers one roller and two roller variants, as well as models with parallel and tilted rollers. DL30 and DL40P are two prominent machines from the series. DL30 features tilted rollers and can handle dough portions of 80g – 210g. The DL40P model, on the other hand, comes with 40cm parallel rollers and can manage 100g – 700g dough portions.

Meconsud also manufactures some of the finest manual dough sheeters. SB500PM-70 benchtop sheeter with 500mm rollers and 700mm (each side) table is ideal for rolling thin dough sheets for pastries, croissants, puff pastry, and pasta dough.

For large industrial bakeries with high-volume needs, the SF600-120 floor-standing dough sheeter is a good option. It features 600mm long chromium-plated rollers with three-phase, single-speed.

Check out more Mecnosud dough sheeters here.

AG Equipment stands as Australia's distinguished importer and retailer of top-tier commercial catering and kitchen equipment.

With over a decade of unparalleled excellence, this Australian-owned brand has carved a niche in offering premium solutions tailored for culinary ventures.

Among their vast array of offerings, the dough roller and dough sheeter machines are noteworthy.

Among the top models, the DSA420TGO Touch and Go dough roller features a patented design automation system, equipped with a touch sensor that automatically turns on the rollers when the operator puts dough onto the machine. This made-in-Italy dough roller also has an adjustable timer and comes with a 250W motor.

JDR520B, a benchtop dough sheeter from AG Equipment, is claimed to be one of the best-quality dough sheeter machines available in Australia in the price range. If your operation requires regular pastry and dough-based production, this sheeter with up to 5kg dough capacity is a good option. Bakeries or other food businesses looking for a freestanding dough sheeter, AG Equipment’s JDR520 can be an effective solution.

Check out AG Equipment dough rollers and sheeters here.

Spending thousands of dollars on a new dough roller or dough sheeter machine can put a strain on your budget and cash flow.

If you’d prefer not to invest a lot of money in a new commercial dough roller or dough sheeter, a cheaper, pre-owned machine might be the solution you’re looking for.

SilverChef’s range of ‘Certified Used’ commercial equipment is mostly ex-rental equipment sourced from businesses we know and trust.

The equipment is typically less than two-and-a-half years old, has been fully refurbished by us, and is backed by a three-month parts-and-labour warranty.

Considering the effective, or useful, life of a dough roller or dough sheeter machine is much longer, you can be sure our Certified Used products have plenty of life left in it.

You can either buy or finance the ‘Certified Used’ (and clearance) equipment on our website. (We’re one of the few financiers, if not the only one, in Australia that funds second-hand commercial kitchen equipment).

Read more about ‘Certified Used’ equipment.

In Australia, the cost of industrial bench dough sheeter machines varies significantly based on the brand, features, and capacity.

The larger the machine or the more high-end features it has, the more pricy it will be.

The brand also has a major role to play.

The AG Equipment commercial benchtop dough sheeter is priced at around $5,500 but a Mecnosud benchtop pastry sheeter will cost upwards of $8,000.

Most of the other brands and models fall within this range, with many options available around the $6,000 to $7,000 mark for a benchtop dough sheeter.

However, you can save money on top-quality brand new or ‘certified used’ industrial bench dough sheeters on easy rent or lease from us.

Check our collection here.

Routine cleaning is the first step in maintaining a dough machine.

Clean it daily following the instructions of the manufacturer.

Remove any dough residue from the parts carefully. Keeping the scrapers and rollers clean will prolong the life of the dough machine.

Take proper care of the belt if you are using a large dough sheeter. Replace the belt immediately if there’s signs of wear.

The motor and electrical parts should be maintained by a professional.

Carry out a thorough preventive check and oil the moving parts at regular intervals.

If there’s a drop in the performance or the machine starts producing more noise than normal, get in touch with a registered technician without delay.

Follow the manufacturer’s instructions to keep your dough machine in the best condition.

There are a number of third-party services available for dough roller machine repair in Australia.

However, it’s always advisable to get the service only from a registered technician. If your machine needs a repair, it’s best to contact your dealer first.

Depending on the warranty and other service agreements, the dealer might provide you with the repair service for a charge even if the warranty has expired.

This manual mechanism is used to adjust the thickness of the dough in some roller models.

The primary components that press and roll the dough to the desired thickness.

A foot-operated control that allows hands-free operation of the machine. Available in some models.

The mechanism to set the distance between the rollers, determining the thickness of the rolled dough.

The hopper is an input area where dough is placed to be fed into the rollers.

A surface treatment on rollers to prevent dough from sticking.

A safety feature that prevents the motor from overheating or getting damaged due to excessive load.

Rollers that can rotate in both directions, offering more flexibility in the rolling process.

A feature that allows the user to adjust the speed at which the rollers operate.

A gauge or display that shows the current thickness setting of the rollers.

A feature in some models that allows the roller head to be tilted or lifted for easy cleaning or dough removal.

The ability of the machine to operate at different speeds, for more precise dough rolling.

We hope this guide has helped you better understand what you need to look for in a new commercial dough roller or dough sheeter machine and how to choose the right model for your needs.

If you want to know more, you can always reach out to the SilverChef team.

Hospitality equipment can be expensive and paying for it outright can put pressure on your business’s cash flow.

Our finance solutions allow you to get the equipment you want now and to pay for it in small, regular amounts out of the revenue it generates for you.

Rent–Try–Buy® not only helps you maintain your cash flow, it gives you unrivalled flexibility to adapt your equipment to the changing needs of your business.

You can upgrade or buy the equipment at any time or, after 12 months, return or continue renting it.

If you decide to buy the equipment, we’ll give you back 75% of the net rent you paid in the first year and 25% of any rental payments thereafter — to put toward the purchase price.